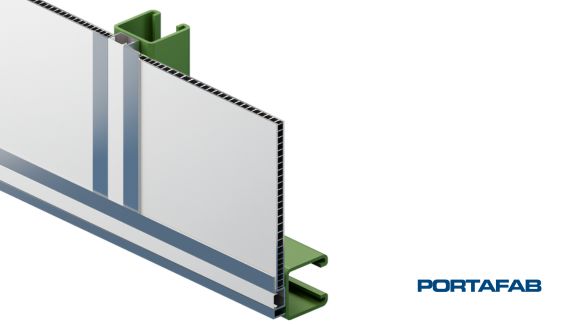

This economical system provides the ability to create a Cleanroom out of an existing room or upgrade a Cleanroom already in use. Furring Wall Systems offer an attractive, cost-efficient wall system for Cleanroom construction over existing block or gypsum walls, fire separation walls, drywall studs, and columns. The functional design also allows it to be installed on strut-type framing to create a mechanical/plenum chase.

Wall panels provide a flush surface on one side while creating a consistent appearance with the ballroom or plenum walls. Universal design allows easy connection to strut or stud framework. Complete flexibility allows for the wall system to be designed for any configuration.

Engineered for use in any ISO Cleanroom classification.

Furring Wall Systems

Furring Wall Systems are available in two panel thicknesses.

Furring 500 on Strut

This 1/2" (12mm) thick wall allows you to create side wall returns and mechanical chases while controlling costs.

Furring on Existing Wall

The 1/4" (6mm) thick wall system can be used to skin existing block and gypsum walls as well as channels to give the cleanroom a consistent appearance.

Performance Highlights

- Wall panels provide flush wall surface on one side.

- Reach unlimited heights.

- Universal design allows easy connection to strut or stud framework.

- Easy removal of panels without disturbing adjacent panels or ceiling for minimum contamination.

- Panels are non-outgassing, non-particle shedding, and anti-static.