PortaFab modular offices and inplant buildings are designed for quick and easy electrical integration. Every system includes standard electrical components to meet your needs, with an optional modular electric package available to simplify installation even further.

Standard Electrical Components

All PortaFab inplant office systems come equipped with:

- Flat LED Lights

- Outlets and switches

- Circuit breaker box

Snap Together Modular Wiring System

Optional electrical option, requiring only an electrician to connect to the power source, and features:

- Snap together cables and outlets

- Pre-wired circuit breaker boxes

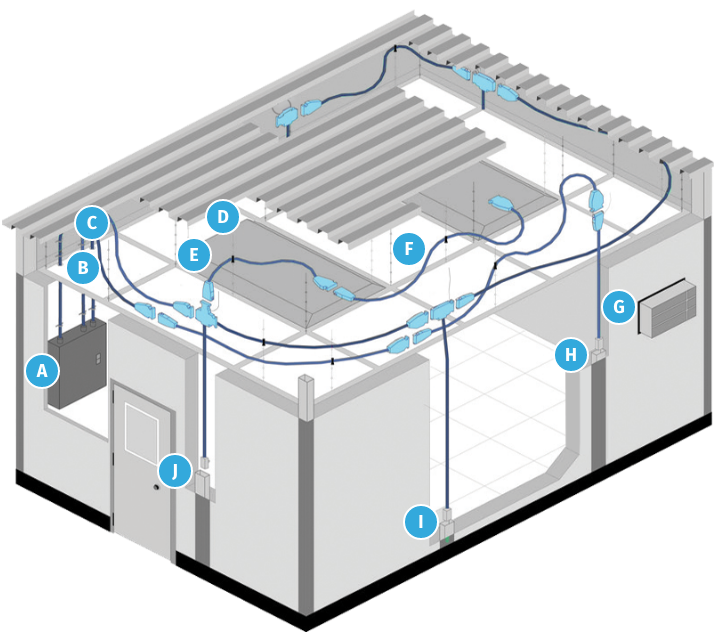

Snap Together Modular Wiring System

Simplify electrical installation with PortaFab's Snap Together Modular Wiring System, a pre-engineered package that includes all the components needed to quickly equip your space. The system supports standard voltages of 120, 240, and 277, with optional pre-wired circuit breaker boxes available. These boxes require only an electrician to connect the power source, streamlining the process. For larger offices, 3-way modular switching can be configured to control multiple entry points with ease.

Circuit Breaker Box

240v Converter Cable

120v Converter Cable

2'x4' LED Light Fixture

120v LIghting Fixture Cable

120v LIghting Extender Cable

Modular Climate Control

240v Dedicated Receptacle Drop

120v Duplex Receptacle Drop

120v Extender Cable

120v Switch Drop

Why Choose Modular Wiring?

Here's how it benefits your project:

Lower Total Cost

Reduces labor costs by minimizing the need for extensive electrician work. The system snaps together, and the electrician only needs to connect the power source to the breaker box.

Faster Installation

Achieve up to 75-80% time savings compared to conventional wiring. Perfect for tight schedules and efficient project management.

Flexibility

With pre-wired fixtures and PNLs, the modular electric package can be reconfigured and reused in the future if a change to the building design is required.

Safety & Reliability

Factory-tested components meet UL183 and NEC 604 standards, ensuring reliability and compliance.

Easy Wiring Integration with PortaFab's Systems

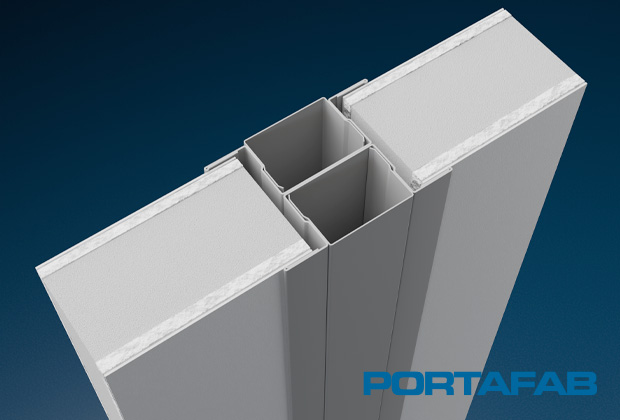

PortaFab framing systems include innovative features to simplify wiring and cabling:

Wiring Studs

Two-piece construction of the stud allows for cabling on both sides of the stud.

“Snap-in” Cover Plates

Provides a clean, professional look while enabling quick access for inspections.