Create freestanding walls quickly and cost effectively with minimal waste and shorter installation time than traditional construction. The modular design also allows our freestanding wall systems to be moved or relocated quickly, easily and inexpensively.

Create Interior Office Space & Defined Work Areas

PortaFab’s extensive line of modular wall systems is ideal for creating interior offices and partitioning work spaces without extensive space renovations.

Framing systems can be painted in many colors (including custom colors) and can be customized with a variety of panel options.

Structural Integrity

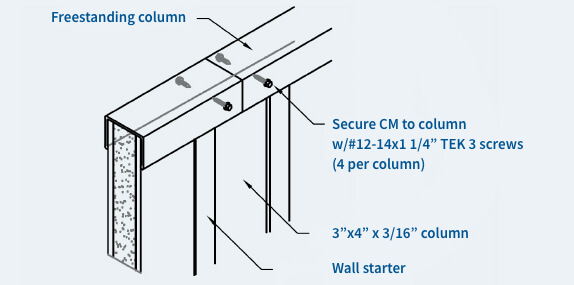

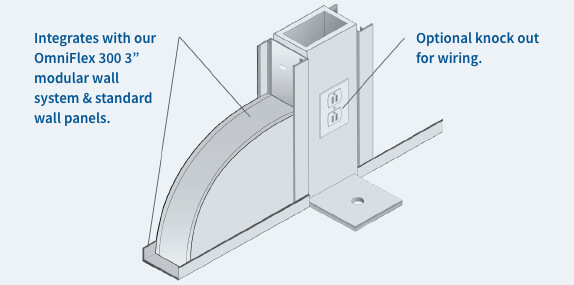

Our 3" steel wall system combines with the freestanding wall support component to establish self-supporting walls in almost any location. Meeting the requirement of 5 lbs. per lateral load for walls exceeding 60 inches, these walls are more robust than typical office partitions and can withstand considerable wear and tear.

Freestanding Column

The 14 gauge steel top cap helps provide durability and support for even the toughest industrial applications.

Floor Anchor

Provides necessary stability to meet 5 lb. per square foot load requirement.