Our client is a known leader in the design, manufacture, marketing and distribution of compact equipment for construction, rental, landscaping, agriculture, grounds maintenance, government, utility, industry and mining. In order to maximize operational efficiency, our client required the installation of an environmental room at their headquarters in order to contain the processes and equipment used in paint finishing and coating applications.

Project Overview

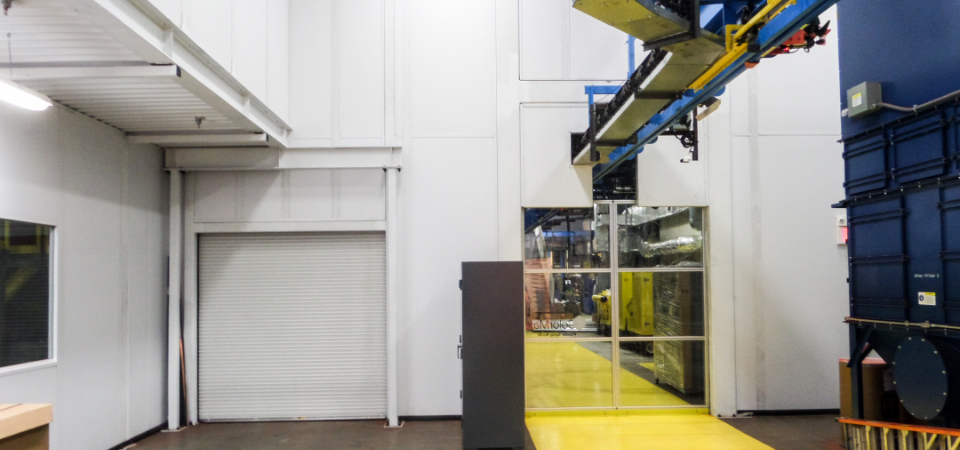

Application: 32’ X 88’ X 24’ Tall Paint Finishing Enclosure

Product: PortaMax 4-5/8 & OmniFlex Wall Systems

Benefits Provided:

- Effective environmental control

- Timely installation with minimal disruption to plant

- Met 24’ height requirements

The Solution

Based on a positive past working relationship and knowledge about the inherent benefits of building with modular systems, the client reached out to PortaFab to discuss a solution, who in turn, passed the lead on to our distributor. After specifying the plans with PortaFab’s sales and engineering teams, our distributor proposed a tall wall modular solution that would meet the clients structural requirements in addition to their desired wall finish and appearance.

The Result

The resulting installation utilized our PortaMax and OmniFlex wall systems to create 32’ x 88’ x 24’ tall enclosure to house the entire paint finishing processes within the plant. The finished design integrated with the existing walls of the facility for a consistent look throughout the plant.

This design also utilized automated roll up doors on each end of the enclosure to facilitate the quick entry and exit of equipment while also accommodating entry and exit areas for the crane to carry equipment in and out of the painting booth.

The final project was completed on time and within budget resulting in increased production of painted components for our client while minimizing the effect of the painting processes on the rest of the facility.