In order to meet the inspection standards already in place at a manufacturing facility in Europe, our client's U.S. plant needed to install a cleanroom to enclose an area where the quality control engineers inspected the generators. While the plans technically just called for a "White Room," the client specified a class 100,000 cleanroom that would integrate with existing systems.

Project Overview

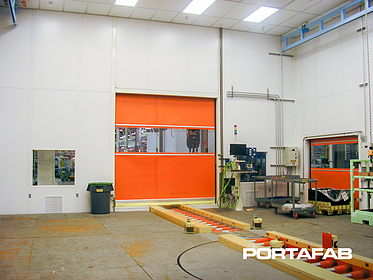

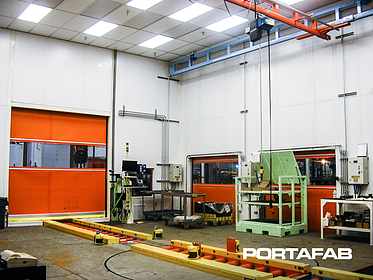

Application: Class 100,000 (ISO 8) cleanroom for generator inspection process

Products:

Benefits Provided:

- Allowed operation to comply with quality guidelines from major customer

- Integrated with conveyors and bridge crane with minimal plant disruption

The Challenge

The cleanroom needed to be retrofitted into an operational facility and the space allocated for the structure had some serious design challenges.

Specifically, it needed to be installed under a mezzanine structure that had a bridge crane above it and very little plenum room. In fact, the cleanroom needed to be almost flush with the mezzanine leaving very little room for assembly.

The Solution

Because the client is consistently developing new products and adapting its manufacturing operation to accommodate fluctuations in demand, they were already set on using modular construction to create this area. The question was whose system to use and what kind of design and installation service could the manufacturer provide.

Working closely with its local distributor, PortaFab traveled to the the client's facility and worked with teams from both companies to custom design a cleanroom that incorporated the restrictions of the overhead space while providing the structural integrity to support the filtration and HVAC systems.

To reduce costs, engineers specified the PortaMax 458 XTRA TALL steel wall system with steel fire and sound wall panels. These non-combustible panels, constructed of a polystyrene insulating core sealed between two 1/2" thick gypsum panels, laminated with 24-gauge steel exteriors provided excellent durability and sound control while meeting all necessary building codes. Once the design was complete and the system was fabricated, PortaFab personnel traveled to the facility again to aid with the installation and ensure that the cleanroom and all of its components were installed as designed.