A major automotive company’s stamping plant wanted to create an enclosed area that would both partition and display an innovative new manufacturing technology. The goals was to essentially create a “Center of Excellence” within the existing manufacturing plant.

Project Overview

Application: Segmented process area visible within the plant

Products:

- OmniFlex 300 Freestanding Wall System

- Steel Fire & Sound Wall Panels

- 48” x 58” x 1/4” Tempered Safety Glass Windows

- 14 Gauge Steel Top Cap

The Challenge

- A freestanding, standalone wall system that could reach height of 10’

- Wall panels and glass that could withstand the rugged industrial environment

- Glass inserts that would provide optimum visibility

- Easy to clean materials as space would serve as a showpiece

- Integrated doors to allow access of heavy and bulky equipment

- Angled corners to fit around support beams and maximize space utilization

Benefits

Created partitioned

process area

Utilized existing lighting, HVAC and fire suppression systems

Pre-engineering design allowed the manufacturer's maintenance staff to install

Flexibility to take down and repurpose at a future date

The Solution

A locally certified PortaFab Distributor worked with PortaFab’s engineering team to create an optimal solution that satisfy every one of the manufacturer's specific needs while still utilizing PortaFab’s pre-engineered components.

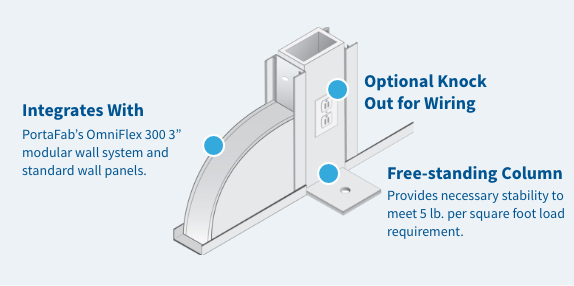

Framing System

For the wall’s framing system, PortaFab’s freestanding OmniFlex 300 wall system was specified for its ability to meet the 5lb. per square foot lateral load requirement for interior walls over 60” tall.

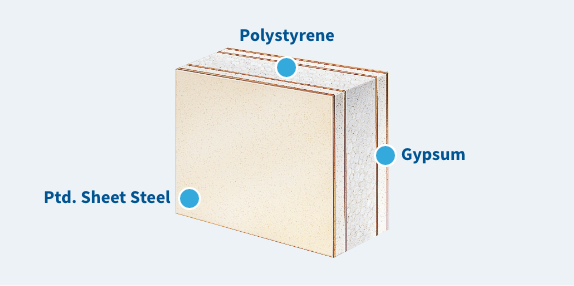

Steel Fire & Sound Panels

To provide the desired durability and visibility, PortaFab’s Steel Fire & Sound panels with extra tall tempered glass panels were specified. The glass windows were positioned 4’ off the ground to achieve the look the manufacturer desired while the steel panels were painted with an easy-to-clean white finish.

Maximize Space

Finally, PortaFab engineers worked with the manufacturer to integrate doors into the enclosed area and utilized 45 degree angled corner frames to fully maximize the designated space available within the plant’s support columns.

Quick & Cost Effective

Once complete and installed, the manufacturer had truly accomplished its goals. The steel and glass enclosure effectively showcased the area as a Center of Excellence while also helping control quality, sound and access. Best of all, the pre-engineered solution was designed and installed quickly and cost-effectively and has the flexibility to adapt to future changes.