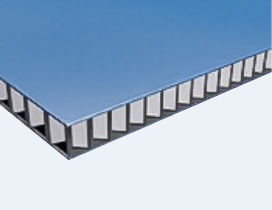

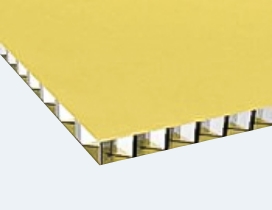

When applications require a lightweight, high strength composite panel, aluminum honeycomb panels are often the best solution. The cell size, grade of aluminum, depth of the material, and thickness of the cell wall are all variables that can be specified to create a honeycomb panel with the best properties for your application.

As a general rule, these panels have the following attributes:

- Extremely Low Weight

- Excellent Strength

- High Resistance to Moisture

- High Resistance to Corrosion

- Excellent Thermal Conductivity

- Noncombustible

- High Resistance to Fungi

Standard Aluminum Honeycomb Panels

Choose from our large selection of standard wall panels.

Types & Uses for Aluminum Honeycomb Panels

- Perforated Panels - Flow-through wall panels for increased air and light diffusion.

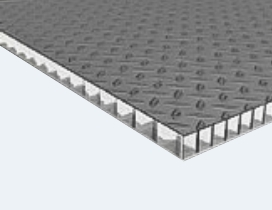

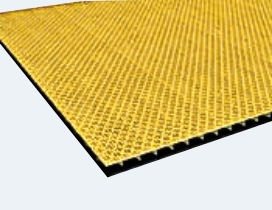

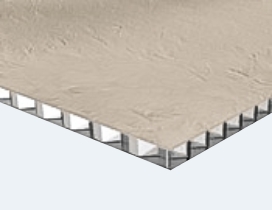

- Tread Plate Panels - Structural wall panels with safe walking surface on top.

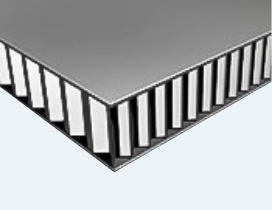

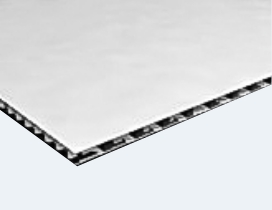

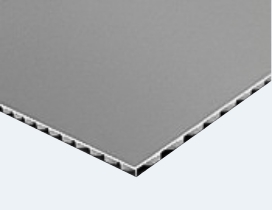

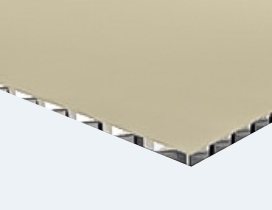

- Aluminum on Aluminum Panels - Standard aluminum wall panels used for a wide variety of applications.

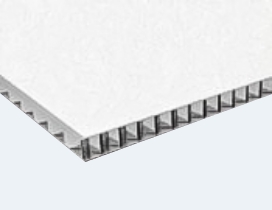

- Cleanroom Panels - Non-outgassing, non-particulating, chemical resistant panels ideal for controlled environments.

- Marine Panels - Durable, lightweight panels with excellent corrosion resistance for marine applications.

- Signage Panels - Designed to meet wind load requirements and accommodate reflective coatings used in sign industry.

- PVC Coated Panels - Panels can be chemically welded for a seamless, monolithic surface necessary in certain controlled environments.

- Museum Panels - Engineered panels ideal for archiving artwork, mounting canvases, and designing gallery exhibits.

- Hurricane Panels - Panels designed to meet high wind loads and resist small flying debris.

- Curtain Walls - Architectural panels available in a variety of panel edges, thicknesses, and densities.

- Ceiling Panels - High strength architectural panels designed to be used as walkable ceiling systems.

- Soffit Panels - Architectural panels available in a variety of panel edges, thicknesses, and densities.

Why Use Aluminum Honeycomb Panels?

Aluminum honeycomb panels are a type of building material that is commonly used in the construction of aircraft, boats, and other structures. The panels are made from a sandwich of two aluminum sheets with a layer of honeycomb-shaped cells in between.

One of the key advantages of aluminum honeycomb panels is their strength and durability. The honeycomb structure of the panels provides an exceptionally high strength-to-weight ratio, making them ideal for use in applications where weight is a critical factor.

In addition to their strength and durability, aluminum honeycomb panels are also known for their thermal and acoustic insulation properties. The honeycomb structure of the panels is effective at trapping air, which helps to insulate the panels and reduce the transmission of heat and sound.

Aluminum honeycomb panels are a versatile and effective building material. Their strength, durability, and insulation properties make them an ideal choice for a wide range of applications.