PortaFab's Modular Cleanroom Wall Systems offer advantages such as flexibility, reduced construction time, minimized disruption, consistent quality, and financial savings compared to conventional construction methods. Modular Cleanrooms Wall Systems also accommodate the need for adaptability, enable faster installation, minimize job site disruption, maintain consistent quality, and often result in lower lifetime costs and environmental benefits.

Two Customizable Modular Cleanroom Systems

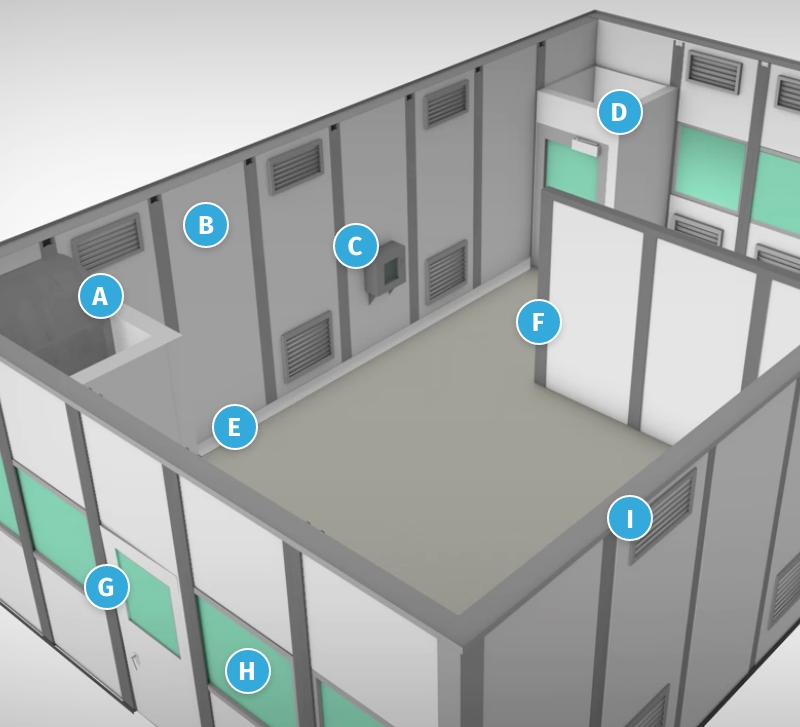

The PortaFab Cleanroom line consists of two separate Modular Cleanroom Wall Systems, each with numerous components to meet your specific ISO needs. PortaFab's Modular Cleanroom Wall Systems can be seamlessly integrated with each other, along with a variety of windows, ceiling systems, and doors.

CleanLine Wall Systems

Use the CleanLine System to build ISO 4 to ISO 8 Cleanroom environments. It is also a cost-effective option for simpler tasks like basic process control for air quality, temperature, or humidity.

FabLine

Use the FabLine System to build ultra-clean facilities meeting the strict environmental requirements of the precision microelectronics and nanotechnology industries.

Designed For Flexibility

The flexibility of our Modular Cleanroom Systems is a result of their post and panel design, which allows for easy expansion or modifications if and when future business needs change. We offer a variety of standard and custom panel options ranging from steel to fiberglass that can easily integrate with our wall systems, depending on your specific application or requirements.

Air Design

Numerous Wall Panels

Integrated Pass Throughs

Air Showers

Wall/Floor Coving

Wall Partitions

Standard and Custom Doors

Multiple Window Styles

Integrated Air Grilles

CleanLine S3000 Cleanroom Wall System

S3000 walls are ideal for creating stand-alone Cleanrooms for the medical device industry.

PortaMax 458 XTRA-TALL Wall System

The PortaMax 458 provides extra tall walls for creating Cleanrooms with increased ceiling heights.

PortaMax 500TB XTRA-TALL Wall System

The PortaMax 500TB is a thermally broken structural stud post for creating self-supported cleanroom envelopes up to 23' tall.

Furring Wall System

The Furring Wall System can be used as a cost-effective option for lining existing walls.

FabLine Framed Wall System

Designed for extensive bulkheading around tools, this system features vertical and horizontal members that are easily connected to each other to simplify construction and provide airtight deals around equipment tooling for minimum loss of room pressurization.

FabLine Batten Wall System

The Batten wall system is a cost-effective alternative to Framed Systems for areas which do not require extensive bulkheading but can benefit from a double-flush surface partition system.

FabLine Furring Wall System

The Furring Wall System is a cost-effective solution for installation over existing block or gypsum walls, drywall studs, and columns.