Question: What is the difference between a single pass and a recirculating cleanroom?

To better understand the difference between a single pass cleanroom and a recirculating cleanroom, one should first consider that virtually all cleanrooms utilize a process where air is pushed through fan filter units into the room and then transferred out of the room. The primary difference between the two designs relates to where the purged air is routed. A single pass cleanroom sends the filtered out into the surrounding area while the recirculating cleanroom returns the air through a plenum to be recirculated into the cleanroom.

Airflow Design Patterns

The airflow design pattern is a key design feature for any cleanroom. To achieve required environmental conditions, the air in a cleanroom is purified using High Efficiency Particulate Air (HEPA) filters which are designed to meet any classification. See the difference between single pass and recirculating airflow designs in the drawings below:

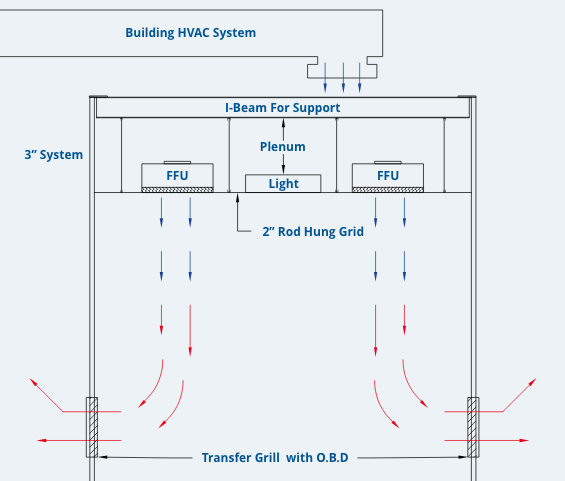

Single Pass Design

In a single pass design, ambient air is filtered into the cleanroom and transferred out into the surrounding building space.

Single pass designs are commonly used in environments that do not require temperature and humidity control.

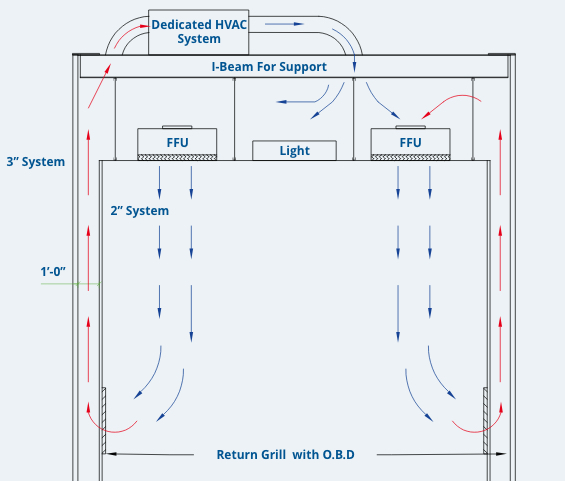

Recirculating Air Design

In a recirculating air designs, air handling units condition the air, which is drawn through low wall returns and into the ceiling plenum.

These designs are typically used for cleanrooms with temperature or humidity requirements, and to isolate the environment for greater process control.

Key Differences

Recirculating vs. Single Pass

Tim Loughran, our cleanroom design expert walks through the key differences.

Get Started

PortaFab offers a complete line of modular cleanroom systems for building both single pass and recirculating cleanrooms. Our cleanroom line is supported by a nationwide network of contractors who can help you design and specify the best cleanroom for your application.